Capabilities

We provide complete ‘concept-to-manufacture’ services including part design, material specification, prototyping, injection/blow mold design and sourcing, and finished assembly.

Market incluiding industrial packaging, construction, transportation, aerospace, consumer, recreational, medical laboratory, appliance and electrical.

Engineering

Wolverine has the engineering experience required to make your product a reality. Whether you only have an idea of the plastic you need or a finished plan ready for manufacture, our expert staff is ready to make your product a reality. Wolverine can provide engineering advice as needed to make your product more effective from reducing costs to improving design.

Manufacturing

Wolverine is dedicated to quality throughout the manufacturing process and has the expertise and tools to guarantee it. From set-up to machining to post-processing, our manufacturing process is designed to provide the highest quality service for our customers’ products.

Manufacturing Capabilities

Our manufacturing processes include injection molding, blow molding, butyl rubber compounding and laminate extrusion, and assembly. Each process is supported by our own Quality System to ensure specification compliance with our customers’ specific needs.

Manufacturing Service and Support

To ensure your application and regulatory requirements are satisfied, we employ robust quality management systems at multiple facilities, and/or ITAR compliant. Our teams are dedicated to maintaining the highest quality standards, records management, and traceability every step of the way.

Custom Solutions

Many of our customers come to us with just an idea. Our fabrication specialists are to help bring your project to life, even if you haven’t put it on paper yet. All you need to do to get your project started is to offer as much detail to your vision as possible. Bring in dimensions, the application, pictures, or any example of what you want the finished project to look like.

Robotics & Automation

We’re always looking for ways to improve our services at Wolverine, one of the ways we’ve done this is by integrating robotics and automation into our manufacturing process. Robotics and automation decrease the time it takes for your products to be produced saving you both time and cost.

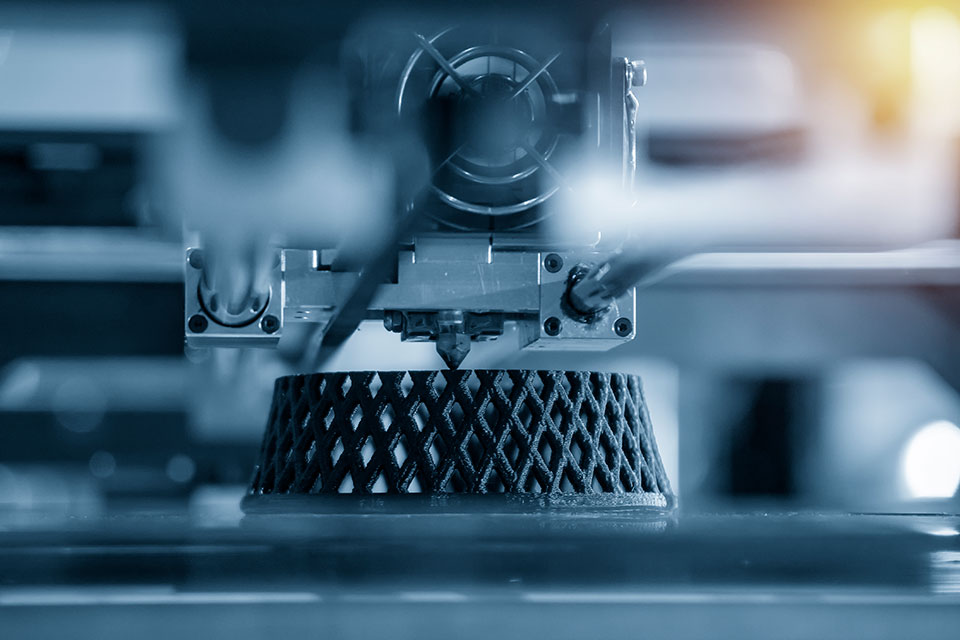

3D Printing

3D printers create three-dimensional parts directly from CAD models by building material layer by layer until a complete physical part is formed. As 3D printers require no tooling and minimal setup time for a new design, the cost of producing a custom part is greatly reduced in comparison with traditional manufacturing processes.

Wolverine also produces small run productions. Just fill out the quote form and we will be happy to quote your project.